| Cable type |

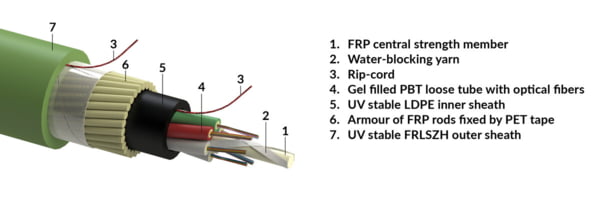

Stranded loose tube cable

|

| Inner jacket nominal thickness [mm] |

1.0000000000 mm

|

| Armour |

Fiber reinforced plastic rod armoured (FRPA)

|

| Flammability - vertical cable bundle test method |

EN 60332-3-22 (cat. A)

|

| Halogen free, Acid gases test method |

EN 60754-2

|

| Fiber color coding |

1.-12.: red, green, blue, yellow, white, grey, brown, violet, turquoise, black, orange, pink

|

| Smoke density test method |

EN 61034-1, EN 61034-2

|

| FRP/coat. CSM nominal thickness [mm] |

2.5

|

| FRP rods (armour) nominal diameter (mm) |

1.0

|