- Компанія

- Каталог

- Twisted Pair Cabling

- Connection Modules

- Installation Cables

- Patch Cords

- 19" Patch Panel

- Outdoor Distributors

- FM45 Connectors and accessories

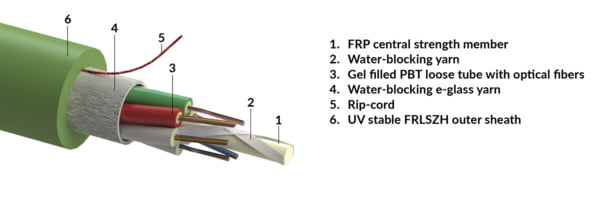

- Fiber Optics

- Twisted Pair Cabling

- Новини

- Гарантія

- Семінари

- E-Business

- Автоконфігуратор

- Сервіс

- Контакти